Outotec Turula

Global leader in minerals processing technology

Reaching new levels with WeldEye welding management software

Outotec Turula streamlined its welding management practices with WeldEye and saved hundreds of hours per year on documentation. In addition, solid proof of welding quality and compliance with quality standards strengthened the competitiveness of the company even further.

Outotec Oyj is a Finnish high technology company that specializes in designing and developing tailored process machinery solutions and life cycle services for mining, metal, energy and water industries. With 4800 employees, operations in 25 countries and business in 80, the company is known for innovative products and solutions that create value for the customer from natural resources in the most sustainable way.Out of Outotec’s five production facilities, Outotec Turula Oy is the largest factory with 200 employees and 25 000 m² premises located in Outokumpu, Finland. The Turula engineering workshop produces equipment for metallurgic processes, mainly copper production. The company has always invested in the latest technologies to ensure a seamlessly flowing production process.

Main challenge

With 70 MIG/MAG, TIG and MMA welding machines and 60 full-time welders, Outotec Turula was in need of a solution that would aid in managing a large staff, monitoring welding quality and improving productivity across the entire welding production. Working with demanding materials made it critical to stay within the WPS limits, and competitiveness was directly derived from consistency in meeting quality requirements. In addition, extra hands had to be hired during production peak seasons, which made the management of welding quality and welder qualifications seem like an impossible task without a proper system in place.

The Smart Reader scanning a welding procedure specification.

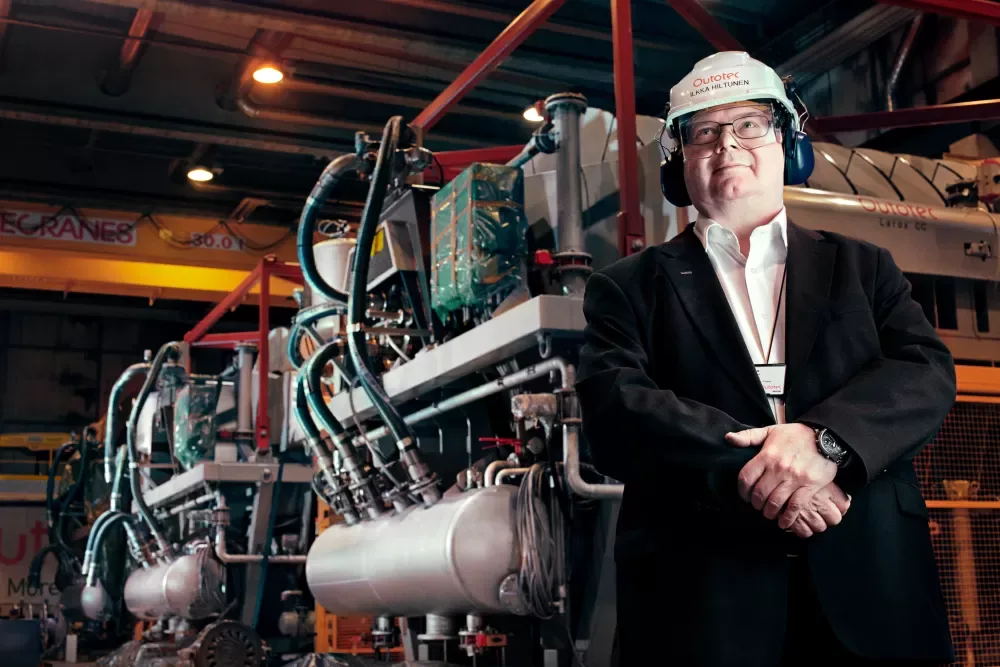

Senior Advisor Ilkka Hiltunen with three robust disc filters about to be dispatched to Brazil.

Outotec Turula's Kari Koistinen, Ilkka Hiltunen, and Rauno Kakkola.

Work in progress at Outotec Turula workshop.

The welding management software solution in use at Outotec Turula's welding production.

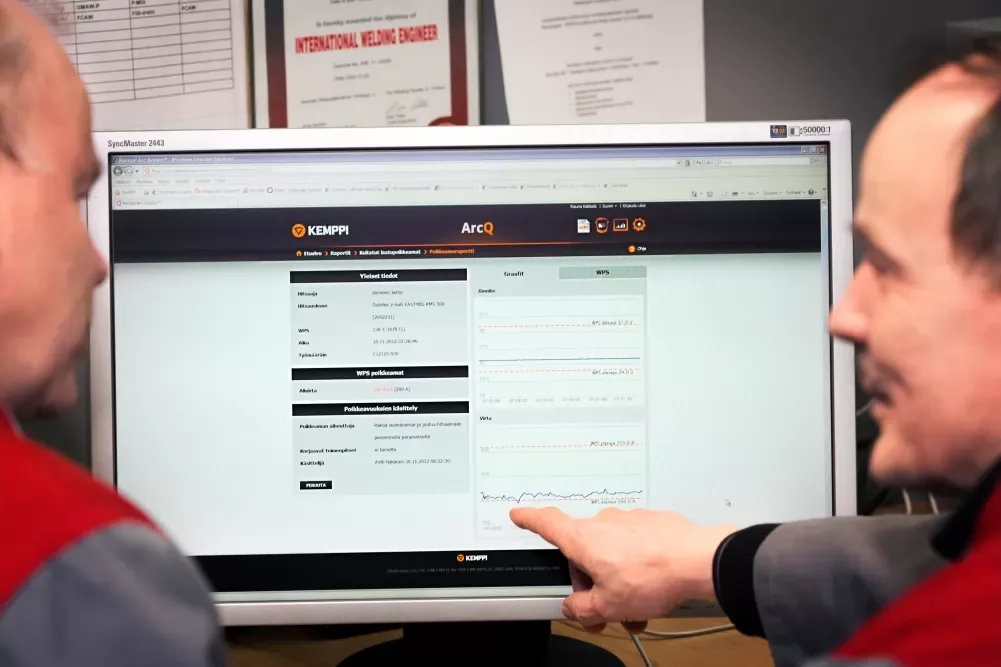

Rauno Kakkola and Kari Koistinen analyzing a deviation report on the software's user interface.

Kemppi SuperSnake at work.

Kemppi's solution

Outotec has developed its partnership with Kemppi by deploying different modules of WeldEye welding management software in phases. In 2012, Kemppi provided the Turula workshop with a quality control module as a concrete way to verify welding quality. With increasing demands on quality assurance from customers worldwide, the software’s ability to produce qualitative data and reports on welding quality was seen as a clear competitive advantage. In addition, it was now easy for Outotec to demonstrate welding production compliance with the requirements of the EN ISO 3834-2 quality standard in regular auditing procedures.

In 2014, Outotec Turula upgraded to the complete welding management software solution, which covered all aspects of the workshop’s welding operations. Not only was it now possible to control and verify top-level welding quality, but also make WPS and welder qualifications management more efficient, and have the complete project documentation ready in just a few minutes.

With positive experiences and proven benefits of use, Outotec is now considering extending the software solution to its other production facilities and subcontractors. As a modern, cloud-based solution, WeldEye is a perfect fit for a globally operating company such as Outotec with the need for a multisite welding management solution.

Featured Solutions

Product family

WeldEye is a universal solution to manage welding production.